By: Jonathan Simon on November 7th, 2023

Why PEX Fittings Leak and How to Identify the Cause

PEX plumbing systems use a different style of fitting than more established CPVC and copper systems. With copper and CPVC, the pipe is inserted into the fitting whereas with PEX the fitting is inserted into the pipe and the two pieces are mechanically joined using other components. This more complex design has created challenges since early in the material’s life when concerns over the health effects of the lead found in brass fittings caused manufacturers to replace lead with zinc in PEX fittings, resulting in widespread failures. Today, installation errors, chlorine degradation and chemical incompatibility are most likely to be the cause of leaking in or around PEX fittings.

Types of PEX Fittings and Why They Fail

There are multiple types of fittings that may be used in a PEX plumbing system, which further adds to the complexity of this system:

-

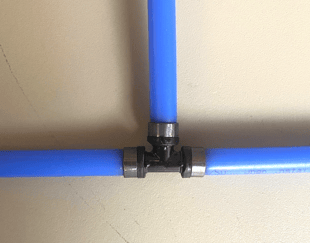

Crimp/Cinch Fitting: In a crimp fitting, a copper or stainless steel ring is placed around the pipe where the fitting is inserted into it and then compressed using a special tool that squeezes the ring around the pipe and fitting. The tool must be properly calibrated to ensure enough pressure is applied to create a seal but not so much as to cause damage. Using a crimp tool that is not calibrated can lead to problems with PEX crimp fittings. “Double crimping” – the act of crimping a ring once and then repeating the action a second time – may also create a poor seal between the fitting and pipe. Additionally, the fitting and crimp ring must be precisely positioned prior to crimping to ensure a proper seal. Tolerances can be as tight as 1/8th of an inch on the position of these components.

PEX Crimp Fitting -

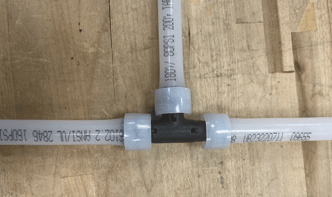

Expansion Fittings: Expansion fittings are even more complex than crimp fittings. An expansion ring is placed over the pipe and a tool is then used to expand the pipe and ring before the barbed fitting is inserted. Contraction of the pipe and ring then secures the pipe to the fitting. Tool calibration is similarly important with expansion fittings to ensure a proper seal. Manufacturers also have different installation practices with some recommending that the tool head be rotated during expansion to avoid damaging the fitting. As with crimp fittings, seating fittings and rings in the right position is required to ensure a properly sealed joint. Tolerances for expansion rings can be as tight as 1/16th of an inch on the position of these components. The rate of contraction for the rings can also vary based on temperature, further complicating expansion ring installations. In cold weather the ring may not contract as quickly as the contractor expects, leading to the fitting becoming unseated.

PEX Expansion Fitting

PEX Expansion Fitting -

Push Fittings: Push fittings, as the name suggests, are connected by pushing the pipe over the fitting with a mechanism inside the fitting pressing against the outside wall of the pipe joining the two components. These removable fittings are generally used for temporary fixes and replaced when possible with a crimp or expansion fitting. Unlike other PEX fittings, the pipe is inserted into the fitting to a specific depth, however because PEX is such a soft material, push fittings require an additional insert stiffener to ensure a secure seal. These fittings are also significantly more expensive than other PEX fittings and can leak due to a failure of the O-ring seal within the fitting, faulty teeth in the gripper ring, or accidental triggering of the removal mechanism.

PEX Push Fitting

PEX Push Fitting

If you suspect the leak is related to poor installation, replacing the fitting using properly calibrated tools and manufacturer-recommended installation practices should resolve the issue. But it’s important to recognize that the issue may not be isolated to one fitting. If the plumber that installed the system used a crimp or expansion tool that was out of calibration or did not follow specific manufacturer instructions, other fittings in the system may be compromised and prone to future leaking. Once you resolve the first issue, check other accessible fittings in the system for weakness.

Chlorine Degradation Near PEX Fittings

Improper installation is a common cause of leaking in and around PEX fittings, but not the only cause.

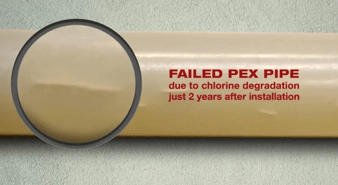

One issue PEX systems have to contend with is incompatibility with local water conditions. PEX is not inherently compatible with chlorinated drinking water, so the material is infused with antioxidants during the manufacturing process that protect PEX pipes and fittings from chlorine. However, these antioxidants are “sacrificial” in that they are consumed by the action of neutralizing the chlorine in the water.

The longer the pipe is in service, the fewer antioxidants remain to combat the effect of chlorine on the pipe. Plus, multiple factors can accelerate the depletion of antioxidants, including aggressive water conditions, UV light exposure, pressures above 80 psi, and temperatures above 140° F. Accelerated chlorine degradation can result in pinhole leaks in PEX pipes and fittings relatively early in their expected life.

Abrasions or cracks that develop through the pipe wall or “popcorning” discoloration of the surface of PEX pipe are signs of chlorine degradation. Unfortunately, because the water flowing through the system is the ultimate cause of the leak, this problem is likely systemic and may require a repipe to fully address.

While these failures actually occur in the pipe, they can appear more frequently near fittings. This may be because of the additional stress the pipe is under near a fitting, especially with expansion fittings. Another potential cause of concentrated chlorine failures near PEX fittings is the turbulent water flow exiting the insert fittings which may accelerate the degradation reaction between the chlorinated water and the PEX piping.

Incompatible Chemicals Can Cause Leaking in PEX Fittings

Finally, contact with incompatible chemicals can also lead to fitting failure. PEX piping is known to have compatibility concerns with closed-cell insulation, organic chemicals, strong acids, strong bases, solvents, petroleum distillates and adhesive tapes.

PEX fittings, however, are made of entirely different materials with different compatibility concerns. Plastic PEX fittings are made from polysulfone or polyphenylsulfone, both of which are highly incompatible with acetone, a chemical commonly found in PVC and ABS cleaners and primers. When exposed to acetone, the plastic fittings will often shatter under limited stress within a matter of days or weeks. Plastic PEX fittings can also be damaged by exposure to UV light and spray foam insulation.

Metal PEX fittings are often made from low-lead brass, which can be subject to corrosion when exposed to certain water or air conditions, as well as when placed in contact with dissimilar metals. With both metal and plastic PEX fittings, failures are generally isolated to the point of contact; however, if a compatibility issue was introduced by way of contractor error, it may occur in multiple locations across a site.

Making the Switch to CPVC

If you’ve experienced multiple problems with leaking PEX fittings or pipes, a complete repipe may be necessary to fully resolve your issue. If this is the case, consider switching to FlowGuard Gold CPVC.

CPVC is the only residential plumbing material that is immune to chlorinated drinking water and the simple chemical bonding process that joins FlowGuard Gold CPVC pipes and fittings creates a one-piece plumbing system from supply through to every fixture. To learn more, download our brochure.