By: Jonathan Simon on February 8th, 2022

Don’t Flex Your PEX – How Bending PEX Pipe Can Lead to Premature Failure

The flexibility of PEX piping allows for sweeping bends that reduce the number of fittings required to install a PEX plumbing system. However, an analysis of a recent PEX failure indicates this convenience to plumbers may come at a steep price for homeowners—increased likelihood of premature failure.

Why PEX Piping Fails

PEX is structurally similar to polybutylene, a plastic piping system introduced in the 1970’s and widely used until the material’s vulnerability to chlorine degradation became obvious and it was pulled from the market.

PEX and polybutylene share common attributes such as their flexibility, joining methods and susceptibility to chlorine degradation. While PEX products are tested for long service life, there are several normal operating conditions which are outside the limits of those tests and can lead to premature failure of the PEX systems through what is called a “stage 3” or pure oxidative failure.

Unfortunately, the number of these failures has steadily grown as more municipalities move to new water disinfectants such as chlorine dioxide. An increasing number of service and re-pipe plumbers have had to replace leaking PEX piping that failed due to these stage 3 chlorine failures.

But while these failures have been on the rise, a recent analysis of a new type of failure may suggest that another form of widespread PEX failure could be on the horizon.

A New Failure Mode

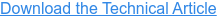

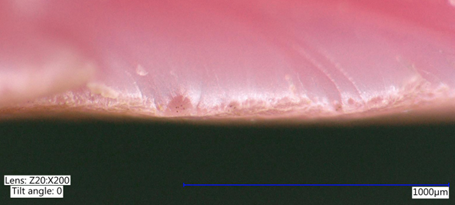

In early 2021, Lubrizol Advanced Materials performed a failure analysis of a ¾” section of PEX-b tubing that experienced multiple through-wall cracks on the hot water side after approximately 10 years in residential service in California. These cracks were unique because they formed around the pipe rather than parallel to the direction of water flow.

The analysis found a chlorine degraded layer less than 0.1% of the thickness of the pipe. Based on the age of the pipe in service, this amount of degradation could be considered normal, and the pipe should have remained in service without failure for many years. Yet, pinhole leaks formed and the pipe had to be replaced.

The analysis indicated that the crack began in the thin embrittled layer that had been degraded by chlorinated water, and then expanded under mechanical stress caused by flexing of the pipe. This type of failure is classified as a “stage 2” failure in chlorine resistance testing.

To understand why the stress that created the initial cracks is occurring, it’s helpful to know a little about how PEX is manufactured. PEX-a and PEX-c are manufactured in a way that locks the cross-linked polymers in a straight-line configuration while PEX-b manufacturing can lock the cross-linked polymers in a coiled position.

When any piping, including PEX, is bent out of its natural state, it places the pipe under mechanical stress. If the pipe’s natural state is coiled, straightening the pipe or bending it in the opposite direction of its initial coil will induce stress; if the pipe’s natural state is straight, bending it will induce stress. When an already stressed PEX pipe is degraded by chlorine, the risk of stress corrosion cracking may be lower because the stress would be considered static. However, when a PEX pipe that has experienced even minimal chlorine degradation is subjected to new bending stress from expansion and contraction or manipulation, the risk of cracking is significantly higher. The stress can force the tiny cracks that occur in the degraded layer to expand to the point where the pipe fails.

Hiding in Plain Sight

One more question remains. If this failure is related to bending PEX, why are we just learning about it now? Two reasons.

First, it can take a few years for the thin degradation layer to form and then several more years for the initial crack to expand through the pipe wall and cause a leak, meaning that the problem typically won’t show itself until the piping is several years old.

The other reason is misdiagnosis. The cracks that appear on the exterior surface of the pipe look like external physical damage. The failed pipe that was analyzed, and other similar failures, have been visually diagnosed as resulting from sources ranging from vibration or rubbing of the pipe against a structural member to a nick from a cutting tool during or after installation. Without a thorough evaluation of the failure, it would be nearly impossible for a plumbing contractor or homeowner to tell the difference between physical damage and this form of chlorine-induced stage 2 failure.

An Asset that Becomes a Liability

One of the main reasons plumbers have embraced PEX is its flexibility and the perceived benefits that go along with it. Unfortunately, this analysis shows that PEX’s flexibility could in fact be a major liability.

With a FlowGuard Gold Plumbing System there is no need to worry about chlorine-related failures. FlowGuard Gold CPVC is inherently immune to chlorine degradation from drinking water. A FlowGuard Gold plumbing system installs as fast as PEX according to a third-party time analysis and has been proven in U.S. domestic water systems for more than 60 years.

You can avoid both stage 2 and stage 3 PEX failures, and give your customers the long-lasting, proven plumbing system they expect, by switching to FlowGuard Gold CPVC. To learn more about PEX stage 2 failures and the analysis that identified the cause, read our technical article.