By: Jonathan Simon on February 26th, 2019

Plastics Pipe Institute Updates Technical Note on Use of PEX in Chlorinated Water

Potable water piping systems have a primary goal: to deliver safe and clean water to drink. Plumbing system materials, therefore, must meet specific performance criteria to ensure they are suitable for use in a potable water supply. Piping materials are tested for their temperature and pressure-bearing capabilities, and in the case of polyolefin materials such as PEX, they are tested to determine their time to failure when exposed to chlorine.

This added requirement for polyolefin materials dates back to the early 1990s when the industry was plagued by massive failures in polybutylene plumbing systems and later failing polypropylene dip tubes in water heaters. These failures were traced to a process called oxidative degradation, which occurs when chlorine-based water disinfectants chemically attack the molecular structure of piping material made from polyolefin plastics.

Piping systems must be able to withstand the chlorine that is part of the standard disinfection process in water treatment facilities, which is why ASTM F2023 was developed as a test standard. The standard employs accelerated tests and extrapolation to determine how long it will take for a PEX pipe to fail from exposure to chlorinated water.

The ASTM F2023 test cannot accurately replicate all actual use conditions, which resulted in the standard stating that the extrapolated time to failure and the actual time to failure can differ based on the conditions. To help raise awareness of the limitations and proper application of ASTM F2023, The Plastics Pipe Institute (PPI) issued a technical note as a service to the industry to provide builders and plumbers information regarding the use of PEX tubing in potable water applications.

Key Statements from PPI Technical Note 53

The most recent PPI technical note, issued in 2018, stated:

Frequent or continuous exposure to water conditions beyond those used in ASTM Test Method F2023 (i.e. aggressive water quality with an ORP above 825 mV and/or pressures above 80 psig and/or temperatures above 140°F) may cause premature oxidation and eventual brittleness of the PEX material, reducing its ability to meet long-term requirements.

The technical note recommends that for operating conditions beyond the specified end-use conditions of the respective PEX standards, users should contact the specific pipe or tubing manufacturer to determine whether such conditions are approved for use.

While the ASTM F2023 test requires a calculated 50 year minimum time to failure under the conditions of the test, elevated pressure and/or temperatures in the presence of chlorinated water can result in rapid PEX failure, sometimes in less than 10 years.

FlowGuard Gold® CPVC Is Immune to Chlorine Attack

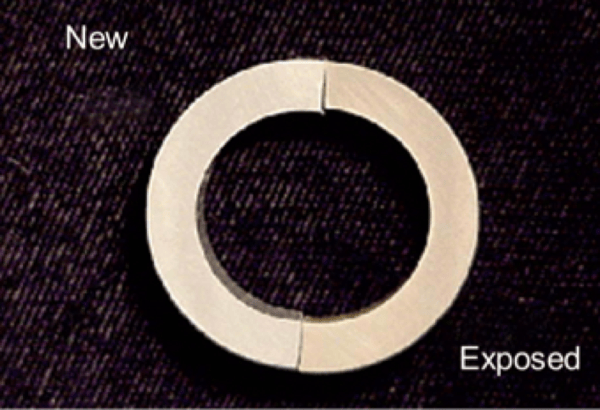

CPVC materials do not require chlorine resistance testing because CPVC is chlorinated, with the large chlorine atoms that surround a CPVC polymer chain blocking the chlorine radicals in chlorinated water so they are unable to reach the chains. This resistance to chlorine will not decrease over time and, as a result, the CPVC system will never fail as a result of exposure to chlorinated water.

Comparison between new and used CPVC pipe

Comparison between new and used CPVC pipe

CPVC pipe and fittings are often installed in aggressive chlorine-delivery systems that operate at chlorine levels several times greater than the normal level of tap water. FlowGuard Gold CPVC, therefore, offers reliable, long-term performance without the problematic and costly plumbing system failures that may occur in systems constructed with polyolefin plastics such as PEX.

FlowGuard Gold CPVC is America’s oldest and most proven non-metallic piping system, with nearly 60 years of proven history and more than 10 million feet installed in American homes and businesses. Contact us to speak to a representative and learn how to make the switch to the superior plumbing system.