By: Jonathan Simon on March 5th, 2024

The Real Reason Frozen Pipes Fail and How to Prevent It

Contractors | Sustainability | residential plumbing | CPVC

Because water expands as it freezes, many people assume that the pressure of the ice pushing on the inner wall of a pipe is what causes pipes exposed to freezing temperatures to fail.

But that’s not what happens.

What actually happens is that ice forms first on the inside wall of the pipe and grows inward until it forms a plug that blocks the pipe. The ice plug then grows down the length of the pipe, pushing against trapped liquid water remaining in the pipe. Because water is incompressible, this causes water pressure in the pipe to build. When pressures exceed the material’s short-term burst pressure strength, the pipe will fail.

Why It Matters

Flexible piping materials like PEX aren’t able to avoid damage from freezing by expanding to absorb the volume change between liquid water and ice.

In fact, short-term burst pressure strength is more important than flexibility in dealing with freezing within the pipe. Here are the typical short-term burst pressure ratings for the most commonly used residential plumbing materials:

- PEX: 475 psi

- Plumbing-size CPVC: 1250 psi

- Type L copper: 3000-4000 psi

Other Factors that Influence Failure from Freezing

This doesn’t mean that the ability of a piping material to stretch outward plays no role in mitigating pipe failure. The Plastics Pipe Institute’s TR-52 notes that the expansion of PEX may help relieve some of the pressure created by freezing when the pipe can expand evenly along its length.

But even assuming freezing occurs where the pipe can expand evenly, the comparatively low burst pressure strength of PEX can still result in failure when pressure in the pipe rises significantly.

What’s more, the ability of PEX to expand can decrease significantly as the material experiences oxidation from exposure to chlorine, chloramine or chlorine dioxide. This oxidation produces a thin layer of brittle material on the inside surface of the pipe that can reduce its ability to expand before breaking by 30% to 90%.

When PEX pipes freeze and are unable to expand due to oxidation, a crack forms on the inside surface of the pipe. As the pressure grows, the crack expands and tears through the pipe wall, creating a rupture. If the ice plug melts before the internal pressure causes the tear to burst, the pipe will be left with a significantly weakened area that increases the risk of future failure.

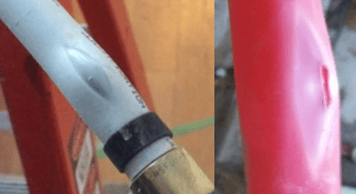

Left: A PEX pipe with a tear caused by freezing that has not yet ruptured.

Right: A PEX pipe that has burst due to freezing.

Six Ways Plumbers Can Reduce the Risk of Frozen Pipes

Whether installing pipe in new construction or responding to a failure resulting from freezing, here are six ways plumbers can reduce the risk of piping failure from freezing.

- Don’t believe the freeze-poof piping myth.

Depending on how long a pipe is exposed to freezing conditions, internal water pressure created within the pipe can easily exceed even the high burst pressure strength of copper pipes and cause a failure. In other words, all pipe materials are vulnerable to freezing and all pipe and fitting materials can leak after a frozen pipe event. There is no “freeze-proof” plumbing system. - Always plan for cold weather.

Just because freezing conditions are uncommon in certain areas, doesn’t mean they never happen. According to the National Oceanic and Atmospheric Administration, the vast majority of the United States can expect the temperature to drop below freezing at least once a decade—and you want the plumbing you install today to last longer than ten years. In addition, the Insurance Institute for Business & Home Safety warns that homes in Southern states can be more susceptible to frozen pipes due to inadequate design and installation practices that leave pipes vulnerable. - Avoid installing pipes in unconditioned areas.

Many building codes recommend against or prohibit the installation of pipe in unconditioned areas, but this may be allowed in some regions. Unconditioned areas, such as attics, crawlspaces, overhangs or exterior walls, are the first to get cold when outside temperatures drop and therefore present the biggest risk for frozen pipes. Running pipe in interior, conditioned spaces with the piping within the building insulation envelope is always preferred. - Use appropriate insulation practices.

When pipe must be installed in unconditioned areas, compatible insulation must be used on the pipe. While pipe insulation will not add heat to the pipe, it can slow the rate of freezing. Additionally, heat trace systems may be used in connection with many piping materials to warm the pipe within these spaces. To determine if an insulation or heat trace solution is compatible with FlowGuard Gold CPVC, use the FBC™ System Compatible Program. - Install pipes under slab foundations instead of overhead.

When dealing with slab foundations, running pipe overhead often risks installation in unconditioned areas. By installing piping beneath the slab, the natural geothermal insulation of the ground will typically be adequate to protect against frozen pipes. In addition, running pipes under the slab can have other benefits to builders and contractors, including faster installations and lower installed costs. The bond created by the FlowGuard Gold CPVC solvent weld process, which creates a one-piece joint that is stronger than the pipe itself, makes CPVC ideal for use under slabs. Always verify that local codes allow installation of water distribution piping under slab. - Seal exterior wall penetrations

Holes or gaps in exterior walls for cable or electrical penetrations can allow cold outside air to reach pipes, creating a “wind chill” effect that accelerates freezing within pipes. Sealing exterior penetrations and gaps can help prevent cold air from flowing around the pipes.

The only reliable way to prevent a pipe from bursting when frozen is to prevent the pipe from freezing in the first place. Regardless of the plumbing material being used, plumbers should take every precaution to reduce the exposure of pipes to conditions that can cause freezing.