By: Jonathan Simon on January 21st, 2020

The Impact of Plumbing Materials on Residential Flow Rates and Water Velocity

In a previous post we discussed the use of the term “or equal” in plumbing specifications and how that phrase is sometimes interpreted to equate PEX and CPVC even though significant differences exist between the two materials in the areas of durability, water quality and performance.

With this post we want to dig a little deeper into the differences in the flow rates between the two materials and how they can impact specification and performance.

Calculating Pressure Drops

To get an objective view of flow rates and pressure drops for PEX and FlowGuard Gold® CPVC piping we used the Plastics Piping Institute’s Plastic Pressure Pipe Design Calculator.

Using this calculator and specifying a flow rate of 4 gallons per minute at a temperature of 73° F, CPVC experienced about 10% less pressure drop than PEX over 100 feet of pipe. A 10% difference may seem significant, but it doesn’t materially impact design.

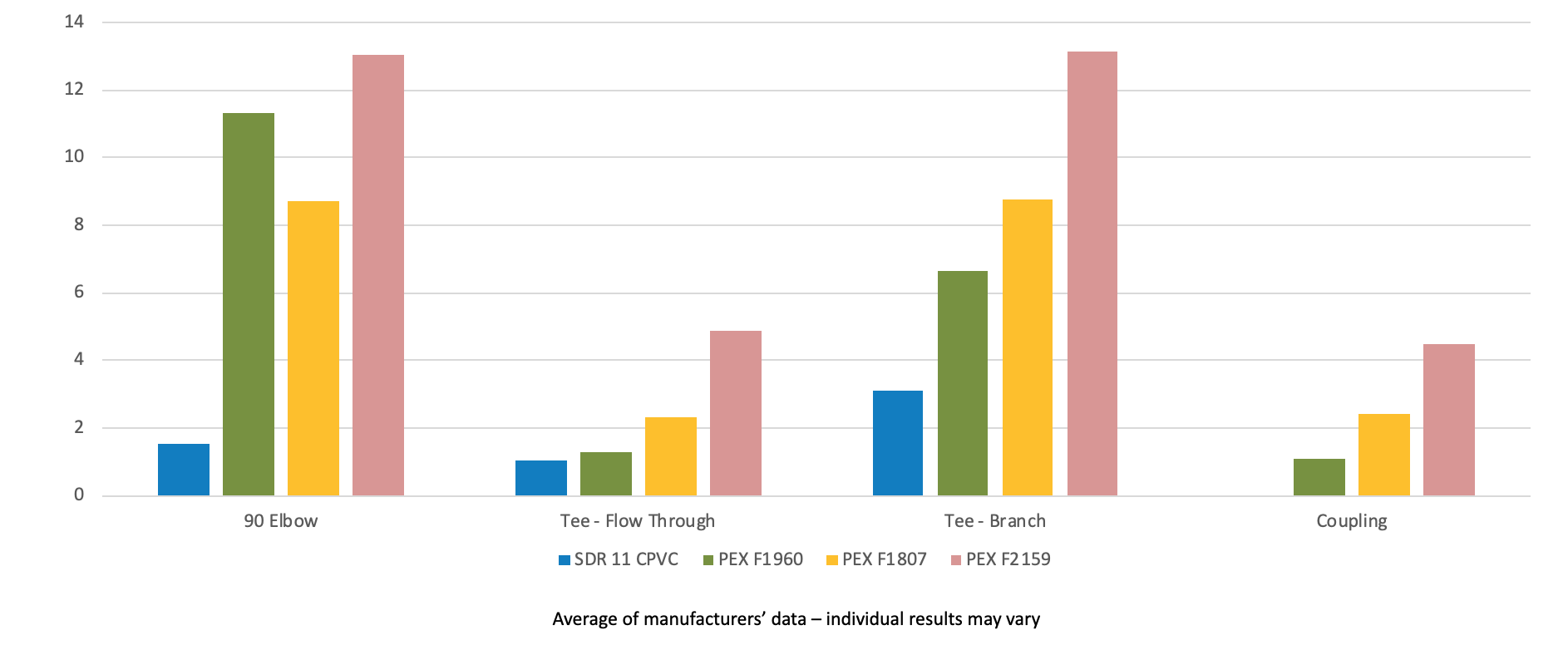

The real impact occurs within fittings. While CPVC uses socket-style fittings, PEX pipe fits around the outside of the fitting, reducing the internal diameter within the fitting. Commonly used PEX fittings include plastic body crimped (F2159), metal body crimped (F1807), and plastic body expansion (F1960).

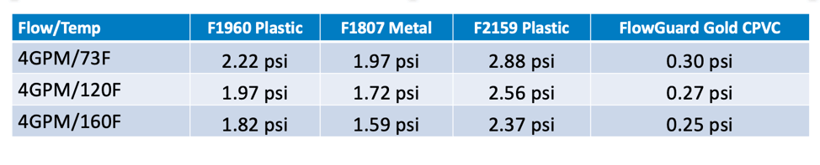

We used the calculator and the average of manufacturer-published data for equivalent lengths to compare the pressure drop in a ½” 90⁰ elbow fitting for FlowGuard Gold CPVC versus each type of PEX fitting. At the three temperatures we calculated, the F1807 metal body PEX fitting had the least impact on pressure drop of the three PEX fittings, but still resulted in a roughly six times higher pressure drop of the “equivalent” FlowGuard Gold CPVC fitting.

Other common ½” fittings had similar results. Note that CPVC couplings create virtually no pressure drop because of the way the pipe fits into the coupling.

Other common ½” fittings had similar results. Note that CPVC couplings create virtually no pressure drop because of the way the pipe fits into the coupling.

PEX manufacturers say that PEX uses about 30 percent fewer fittings than CPVC in a typical installation, but that doesn’t come close to offsetting the higher pressure drops that occur with PEX pipes and fittings. Compared to a PEX system with 30% fewer fittings, FlowGuard Gold CPVC achieves a 74-83% reduction in equivalent length caused by fittings.

The Myth of Full-Flow PEX Fittings

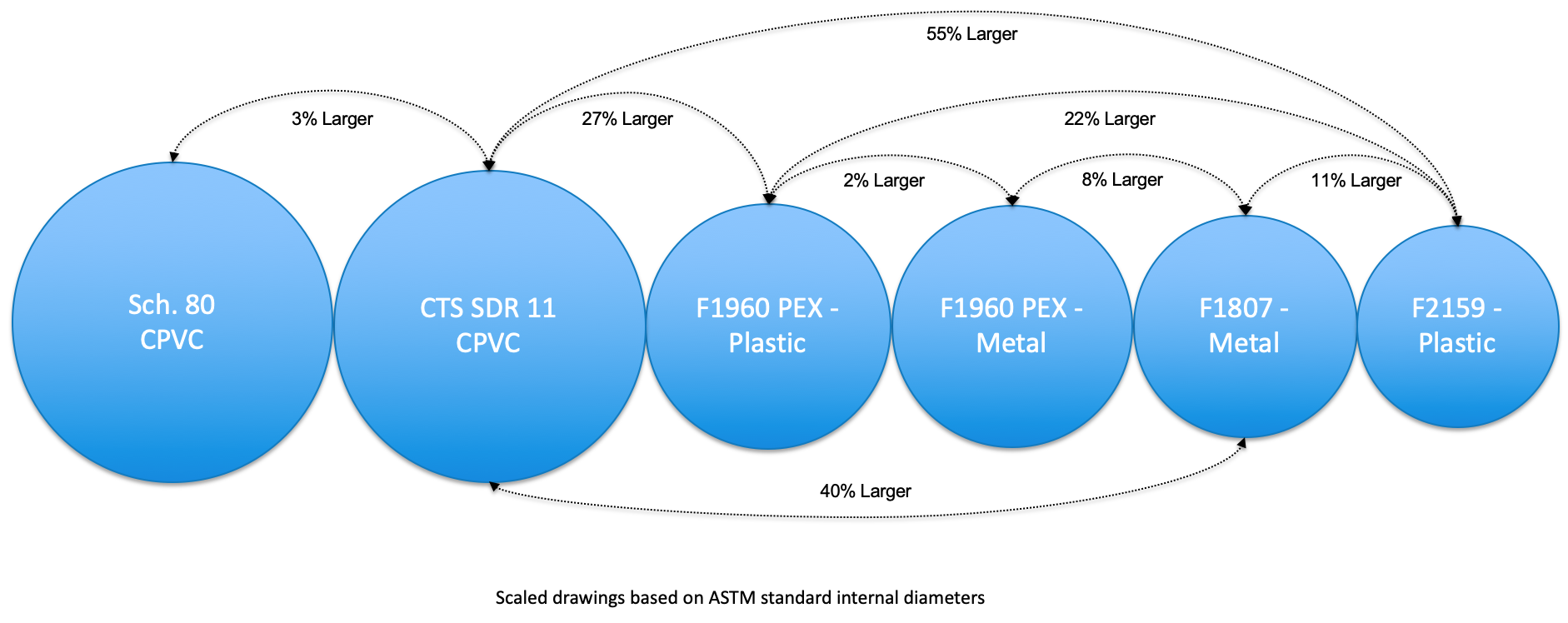

All of those calculations may seem somewhat theoretical until you start to look at water flow. The reality is that even PEX expansion fittings, which are sometimes referred to as “full-flow,” restrict flow rates.

In fact, the difference in the internal diameter between a ½” CPVC fitting and an F1960 expansion PEX fitting is greater (27%) than the difference between an expansion PEX fitting and a PEX plastic body crimped fitting (22%).

How does this translate into flow through the fitting? At a rate of 8 feet per second, the CPVC fitting will cause less than 1% restriction in flow while PEX fittings create a 23% to 54% reduction in flow, depending on the fitting used.

Managing Water Velocity

The experienced engineer may argue that these restrictions won’t have a significant impact on the gallons of water per minute (GPM) flowing through the system and that’s probably true.

However, while GPM will be maintained, water velocity will increase as the water accelerates through the restricted area and jets out of the fitting. At a design velocity of 8 feet per second (fps) in a ½” PEX system, water velocity will reach at least 12.7 fps and as high as 19 fps, depending on the type of fitting used.

This excess velocity can create turbulent zones in the pipe. To avoid this potentially excessive turbulent velocity, engineers may need to significantly reduce the design velocity of the system – in some cases by more than 50%. Engineers may also want to consider this effect in hot water recirculating systems, where several PEX manufacturers limit the design velocity to 2 fps.

FlowGuard Gold pipes and fittings provide full flow and will not cause unusual increases in velocity or introduce significant pressure drop.

These design criteria aren’t the only differences between CPVC and PEX. Because CPVC is chlorinated, it is inherently resistant to chlorine degradation. PEX is not a chlorinated compound and has been shown to be subject to chlorine degradation that can lead to early failure. Because of these limitations, every major PEX manufacturer has limited their warranties so that they may no longer apply in the presence of chlorinated water.

Plumbing design is complicated enough without having to compensate for the restriction in flow imposed by PEX fittings. When performance matters, specify FlowGuard Gold pipes and fittings by name.