By: Jonathan Simon on June 19th, 2019

Understanding the Risks of Chemical Permeation in Residential Water Systems

Homebuilders | PEX | Water Quality

In the first post in our Healthy Home series, we reviewed the important issue of biofilm formation in residential piping and the difference in the biofilm growth potential of PEX and CPVC piping.

For this post, we’ll examine another issue that can impact residential water quality: chemical permeation.

Permeation is the process by which an outside chemical passes through a pipe material resulting in water contamination. Simply put, the molecules of a particular chemical substance, such as a pesticide, may be able to pass through the molecules of piping material because of the porousness and molecular polarity of that piping material.

The key to permeation in residential water systems is the chemical composition of the piping material. The U.S. EPA, in their study on Permeation and Leaching, has found that vinyls are virtually impermeable at low levels of exposure and at high levels of exposure would actually fail before allowing the water to become contaminated. This means vinyl-based pipes and fittings, such as FlowGuard Gold® CPVC piping, effectively mitigates the risk of water contamination through chemical permeation.

That same study found that 82% of documented permeation incidents in the United States occurred in piping materials from the polyolefin family of plastics, which includes polyethylene, polybutylene, polypropylene, PERT and PEX.

The chemistry of permeation is similar to the chemistry of chemical compatibility, however where Lubrizol’s extensive knowledge of chemistry enables us to offer the FBC System Compatible program, polyolefin manufacturers are unable to similarly detailed guidance on avoiding permeation.

PEX manufacturers caution against installing PEX in environments where the piping may be subject to permeation. According to the manual from one manufacturer, “Do not install [PEX in] environments contaminated with solvents, fuels, organic compounds, pesticides or other detrimental materials that may cause permeation, corrosion, degradation or structural failure of the piping.”

Unfortunately, not even PEX manufacturers are fully aware of which materials may cause permeation of their piping systems, as evidenced by one manufacturer whose print line ink was eventually found to permeate through the pipe wall after less than 10 years in service.

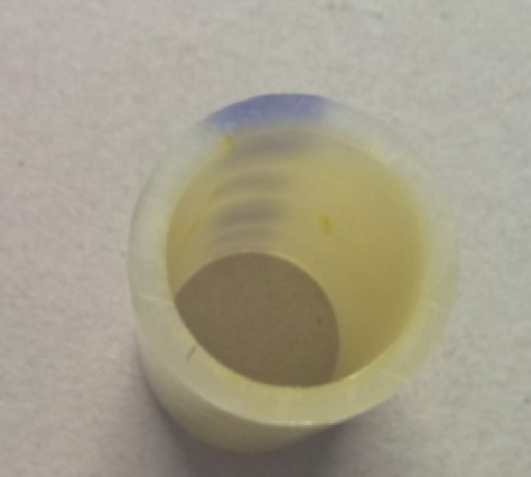

The ink from the print line on this PEX pipe has permeated almost completely through the pipe after less than 10 years.

If the PEX manufacturers themselves have difficulty determining the permeation risk of ancillary products with their piping system how can a plumbing contractor be confident that their PEX piping installations will continue to deliver safe drinking water over the life of the system?

Similar to chemical compatibility, this can become an issue when piping is covered with spray foam or fire caulks or exposed to pesticides after construction. The potential exists for the hazardous chemicals in these compounds to permeate the piping and enter the water supply. These compounds are not typically evaluated to NSF 61 and may pose a threat to human health.

Installed PEX piping covered in both spray foam and pesticide.

That’s why FlowGuard Gold pipes and fittings are the right choice in healthy home building materials. In addition to offering fast and easy installation and cost effectiveness, FlowGuard Gold piping systems are reliable, resistant to permeation and certified under NSF 61 for all water conditions.

If you’ve already installed a PEX system which may come into contact with permeable chemicals, it is recommended that you reach out to both the PEX piping manufacturer and the manufacturer of the ancillary building product and request signed documentation from a chemist or chemical engineer stating that the chemicals present in the ancillary building product will not permeate the piping material during the life of the system, under the systems actual operating conditions for temperature and pressure.

For an easier way to virtually eliminate your permeation risk, ensure water quality and build a healthier home, make the switch today to FlowGuard Gold piping systems.