Plastic Plumbing Systems Can Deliver the Reliability and Performance of Copper When Properly Specified

Many engineers today are designing reliable, high-performance residential plumbing using plastic plumbing systems. But even as specification of plastic plumbing systems increases, some specifications make inaccurate generalizations about plastic piping. The first thing to understand is that there are significant differences between the two plastic domestic water plumbing systems most commonly used in the U.S. today, PEX and CPVC. Knowing those differences is the key to creating accurate and effective designs and specifications.

Comparing Plastic to Copper

Copper has been the basis for most plumbing designs. Like copper, FlowGuard Gold pipes are rigid and use socket fittings, so you can design a FlowGuard Gold system the same way you would a copper system. PEX piping is flexible and uses insert fittings, requiring modifications to adapt a copper design to PEX. PEX manufacturers will “translate” copper designs for PEX plumbing systems, which can be convenient for engineers but can lead to including design elements that the engineer of record doesn’t fully understand or consider in the written specification or submittal approval process. The pressure loss created by PEX fittings must also be considered in the design and may require upsizing the piping to maintain adequate water pressure, at increased project cost.

Plastic Effect on Flow and Pressure

If you’ve heard that plastic piping can create a noticeable pressure drop across the system, that’s true of PEX but not FlowGuard Gold. While CPVC has slightly higher pressure drop than copper, the difference is so small it typically doesn’t affect design. PEX systems have notably higher pressure drop than copper and FlowGuard Gold fittings because PEX insert fittings reduce the pipe diameter at each fitting. The severity of the pressure loss in PEX systems varies by fitting type so it’s important to calculate pressure drop based on the type of PEX fitting being specified. If multiple fitting types are specified or allowed on submittal, the entire system should be resized for each approved PEX fitting system.

Chemical Composition and Water Compatibility

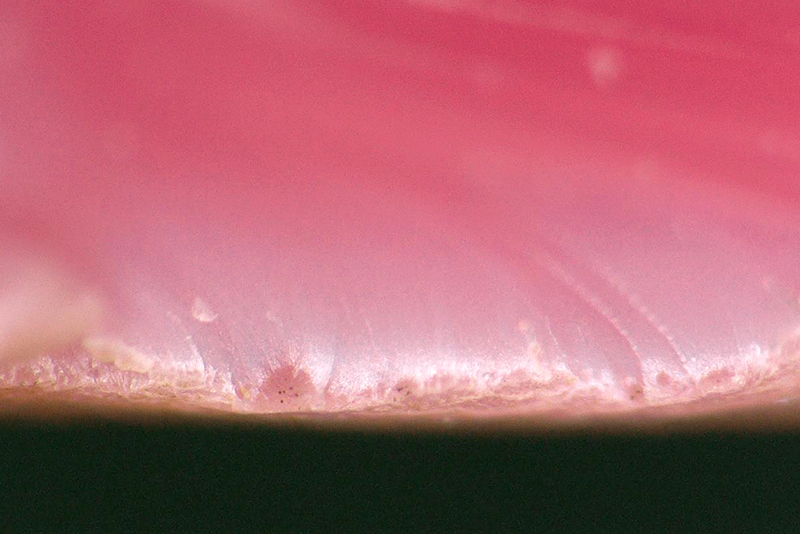

FlowGuard Gold plumbing systems outperform both copper and PEX in resisting damage from chlorine-based water disinfectants that municipalities add to the water supply. As a chlorinated compound, FlowGuard Gold CPVC is inherently resistant to degradation from chlorine-based disinfectants, which can cause corrosion in copper pipes. PEX is even more susceptible to chlorine degradation than copper. Antioxidants are added to the PEX material during manufacturing to neutralize the effect of chlorine on the material, but these antioxidants are sacrificial. As they are depleted, the integrity of the PEX pipe can be compromised, resulting in pinhole cracking or leaking PEX. In some cases,  by the water flowing through it.

by the water flowing through it.

Plenum Ratings

Another factor to consider when specifying plumbing systems is plenum ratings. Codes require that all plumbing piping be listed and labeled to ASTM E84 for flame and smoke performance in a plenum. All FlowGuard Gold pipe and fittings are acceptable for use in return air plenums without special restrictions, allowing FlowGuard Gold pipes and fittings to be installed in the same manner as copper. PEX plenum ratings vary by brand and pipe diameter and are contingent on either spacing the pipes a minimum of 18 inches apart or using plenum-rated insulation or pipe supports.

Plastic Piping and Water Quality

With health and safety becoming increasingly important to clients, engineers should consider the impact of piping material selection on water quality. That means evaluating materials based on the potential for leaching, permeation and biofilm growth. Some brands of PEX are known to leach gasoline components MTBE, ETBE, TBA and Toluene that may exceed the action levels of some states. The PEX material is also permeable, which may allow some chemicals that contact the outside of the pipe to soak through the pipe and reach the water supply, and has a higher biofilm growth potential than CPVC. FlowGuard Gold CPVC is ”virtually immune” to permeation and has one of the lowest biofilm growth potentials in the industry, reducing the risk of harmful bacteria and contaminants from entering the water supply. FlowGuard Gold CPVC is also certified to NSF 61 for water quality under all water conditions and complies with all state water quality regulations.

Understanding Environmental Impacts

If you’re designing for LEED or NGBS certification or working with a developer focused on sustainability, the choice of plumbing materials becomes straightforward. FlowGuard Gold CPVC is the only residential  and

and  . The

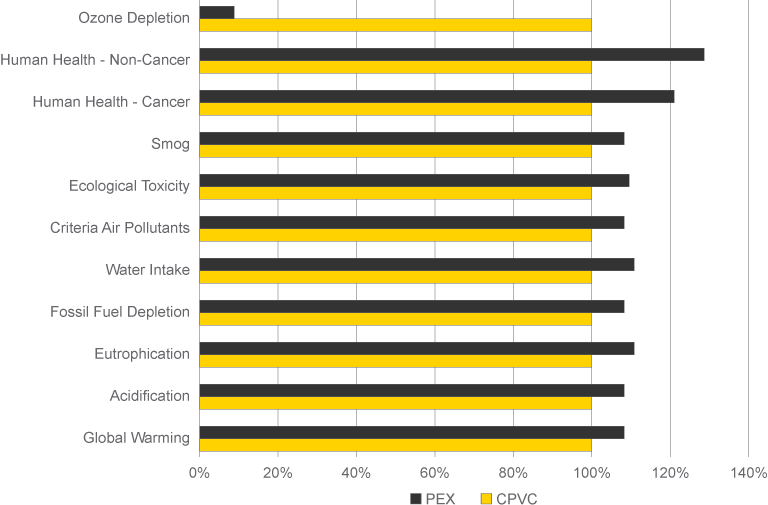

. The  (Building for Environmental and Economic Sustainability) software is another resource engineers can use to compare the environmental impact of building products using the life-cycle assessment approach specified by ISO 14040. The measurement analyzes all stages in the life of a product, including raw material acquisition, manufacturing, transportation, installation, use, and recycling and waste management. Using this tool shows that CPVC is superior to PEX in 10 of 11 categories.

(Building for Environmental and Economic Sustainability) software is another resource engineers can use to compare the environmental impact of building products using the life-cycle assessment approach specified by ISO 14040. The measurement analyzes all stages in the life of a product, including raw material acquisition, manufacturing, transportation, installation, use, and recycling and waste management. Using this tool shows that CPVC is superior to PEX in 10 of 11 categories.

Comparing System Costs

Developers increasingly prefer plastic plumbing over copper because of the significant savings in material costs they will experience. But there are also major differences in costs between PEX and CPVC. An analysis by a leading PEX manufacturer of the plumbing material costs for a three-story building found that copper piping materials for the project would cost $31,478; PEX materials would cost $20,837; and CPVC would cost $10,136. By converting from copper to CPVC, you can help builders achieve significant material savings without compromising plumbing system performance or reliability.

Ensuring System Integrity

If you’re confident designing with copper, you can be confident with FlowGuard Gold CPVC. FlowGuard Gold CPVC has  and conforms to the highest possible industry quality standards for both manufacturing and performance. Plumbers who have worked with copper adapt easily to CPVC, and Lubrizol Advanced Materials supports FlowGuard Gold CPVC with extensive training resources and on-site support. Installed FlowGuard Gold CPVC has the same professional, neat, and organized look as copper, reflecting positively on all involved in a project.

and conforms to the highest possible industry quality standards for both manufacturing and performance. Plumbers who have worked with copper adapt easily to CPVC, and Lubrizol Advanced Materials supports FlowGuard Gold CPVC with extensive training resources and on-site support. Installed FlowGuard Gold CPVC has the same professional, neat, and organized look as copper, reflecting positively on all involved in a project.

Structural Integrity of PEX and CPVC

When any piping, including PEX, is bent out of its natural state, it places the pipe under mechanical stress. When a PEX pipe that has experienced even minimal chlorine degradation is subjected to new bending stress from expansion and contraction or manipulation, tiny cracks can form in the degraded layer of the pipe that can be expanded by stress, increasing the risk of premature failure. To learn more about this failure mode and how it was identified, download our technical article.

Make the Smart Move to FlowGuard Gold Plumbing Systems

The FlowGuard Gold team makes it easy to include FlowGuard Gold CPVC in your specifications. We not only provide full support to engineers specifying CPVC, but we also offer education on common specification errors and oversights with other plastic plumbing systems. Don’t rely on an  . Specify FlowGuard Gold CPVC for your multi-family, hotel and other domestic water distribution system needs.

. Specify FlowGuard Gold CPVC for your multi-family, hotel and other domestic water distribution system needs.